Fireplace in home interior is every homeowner's dream. Unfortunately, certain types of them impose quite serious requirements on the place and method of installation. So, a brick wood-burning fireplace cannot be built in an apartment multi-storey building, and its installation requires a solid foundation due to its enormous mass.

All these disadvantages can be avoided by choosing metal fireplaces as a living hearth. They can be installed by anyone in a convenient way and play the role of a source, spreading heat, and an excellent object decorative decoration rooms.

Simple but at the same time cute design

Advantages

Japan is considered the birthplace of metal fireplaces, although in a simplified version it strongly resembles the domestic “potbelly stove”. Here we are talking about the fact that the original shapes of metal fireplaces came to us from the Land of the Rising Sun, especially for island options. From the above it follows that one of the advantages of fireplaces of this type is the arbitrariness of the style for decorating any room.

The absence of foundation requirements allows you to think about arranging metal structures after the construction of the house. The product can be installed anywhere in a finished and finished room. Mobility allows you to perform reinstallation with a change in the location of the outbreak.

A very big disadvantage of wood-burning fireplaces is that a significant part of the amount of heat leaves the room through the chimney. An increase in efficiency is only possible due to the rapid removal of heat from the firebox.

Homemade stove

Any metal has excellent thermal conductivity, so it will heat up soon after igniting the wood. The transfer of energy to the air in the room occurs at a much higher speed than in the case of a fireplace built of brick. However, this plus easily turns into a minus when the wood is completely burned. The fireplace cools down very quickly and does not accumulate heat.

Manufacturing

It just so happens that even with any degree of availability of different models of fireplaces in the store, we are interested in the question of how to make a metal fireplace with our own hands. Moreover, this interest is driven not only by the desire to save money. Here you can realize all your ideas about the location, shape and decoration of a living hearth. After all the work done with it, immerse yourself in easy chair and a feeling of satisfaction listening to the crackling of wood in the firebox.

Fireplace system with live fire

Before you start constructing a metal fireplace with your own hands, you need to familiarize yourself with a number of aspects that will not only help improve the efficiency of its operation, but are also necessary to ensure the required level fire safety.

- The walls of the fireplace body become very hot when wood burns. By the way, this fact should be taken into account when choosing a room for installation. Under no circumstances should this be done in children's bedrooms. Closely located surfaces must be insulated on all sides, this applies to walls and floors.

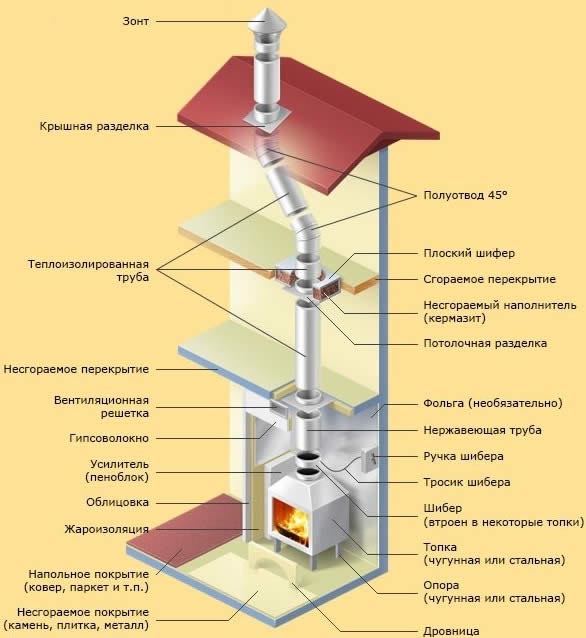

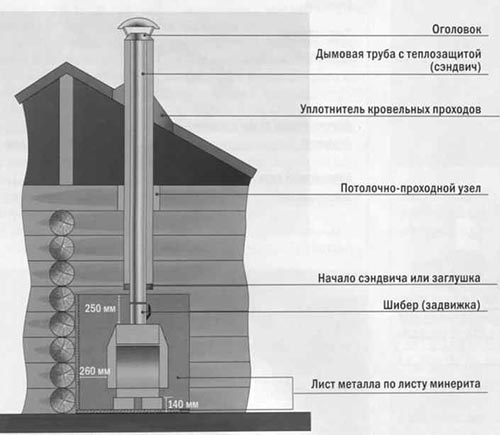

- The chimney, which ensures the removal of combustion products, must be led through the roof to the street, therefore, despite the mobility of the fireplace, you should carefully consider its location.

Homemade fireplace can be made from any material: copper, iron, steel, cast iron. As a rule, iron fireplaces are cheaper in cost, but are inferior in performance to copper or cast iron ones. The thickness of the metal for the main firebox should be 3-5 mm. Having prepared required quantity sheets, as well as corners for making the frame, you can begin to act.

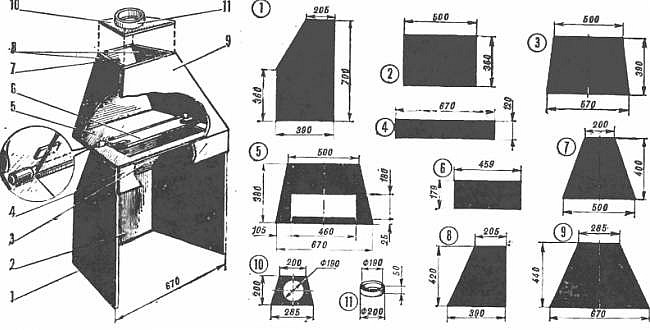

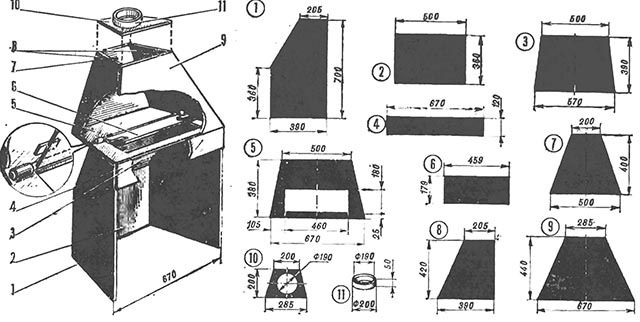

Diagram with dimensions for assembling the frame

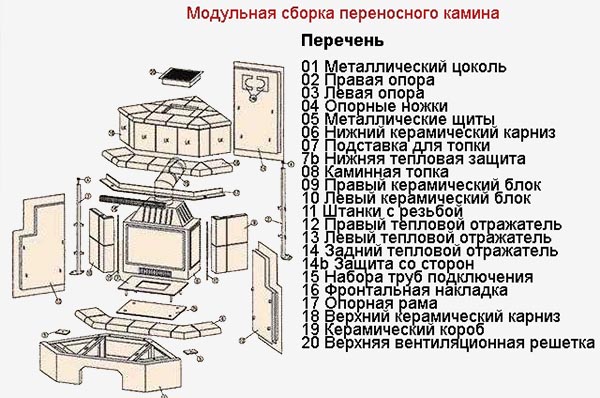

To make it easier to start constructing a metal fireplace with your own hands, you need to prepare the necessary drawings, according to which the sheets will be cut and assembled. Exist finished projects For different types fireplaces, but you can use your artistic skills yourself. Moreover, special requirements is not applied to the design, so modeling and drawings are made taking into account the required geometric shapes and sizes.

You need to start assembling with the fireplace stand. It performs a dual function: on the one hand, the stand insulates the firebox from the floor at a decent distance, and on the other, it provides access to cold air, which is necessary for combustion and is a coolant. The stand will be a rectangular frame that needs to be welded from corners and legs, providing an elevation of 15-20 cm above the floor. The resulting frame is sewn up with a sheet of iron.

The fireplace body will frame the firebox, and not be it (as in a “potbelly stove”). Double walls will allow you to heat the room more efficiently. The air will pass through the space between the firebox and the body and, heating up, enter the room.

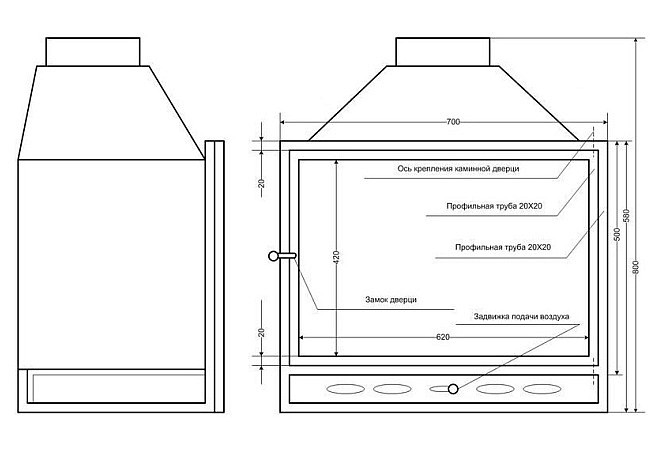

Drawing with dimensions for the future product

The body is made of metal sheets in the shape of a parallelepiped. At the top there is a hole for the chimney. On the front side, hinges are welded to the wall and the door is installed. All these manipulations require skills to work with welding machine. If the initial appearance does not have aesthetics, then you should not forget about surface finishing, with which you can veil all the flaws.

the firebox should be divided into two parts, but not a blank wall is used as a partition, but a valve capable of adjusting the gap between the sections.

- One part will serve for direct combustion of wood.

- The second is used as a smoke collector before it enters the chimney.

This arrangement of the firebox will allow the heat to be retained for some time in order to be removed through the walls of the housing. A grate is installed in the lower part of the combustion chamber and an ash pan is made. It must be large enough to allow ash to accumulate during at least one cycle of fireplace operation.

Chimney from a pipe

Having made a metal fireplace with your own hands, you can begin no less important stage– preparation of the chimney. It is not necessary to produce for him welding work. It is recommended to use ready-made steel pipe.

Exiting the pipe to the roof

The pipes are joined using the provided socket. This is a special extension that allows you to insert one end of the pipe into the other. If there is no such socket, then the edge of the pipe should be cut with metal scissors, and the junction of the pipes should be treated with heat-resistant sealant.

A direct-flow duct is not a mandatory requirement for a chimney for metal fireplaces. Various elbows can be used to direct the smoke along the desired path.

When passing through ceilings, you will definitely have to take care of safety by insulating the chimney. Asbestos material or mineral wool. This procedure is also expected when the pipe exits the roof.

Real live fire

The top of the pipe is covered with a canopy. It will prevent precipitation from getting inside the pipe and will protect against excess debris, and will also prevent sparks from flying out.

Finishing

In absolutely all cases, the resulting fireplace will have to be decorated from the outside. It can simply be coated with a layer of glossy or matte paint. Here you need to remember the elementary laws from the physics course. Dark bodies emit more energy, and since our task is to remove energy, black colors will be a priority.

The fireplace can be finished using special fireproof materials. These include tiles made of ceramics, artificial and natural stone. When gluing tiles, you should remember the thermal expansion of the metal, so the seam gap should be slightly increased.

With an opportunity self-made fireplace, a lot of opportunities open up in front of you to realize your old dream exactly in the form in which she interprets herself. Desire and work in a certain sequence will ensure an excellent result.

Such original designs, like metal fireplace stoves, are made from metal or copper sheets, from blackened or galvanized sheet.

The sheets are connected by rivets or welding. The shape and design of the sheets themselves, their pattern of joints, rivets and combination of geometric shapes is a separate wide artistic theme for decorating a fireplace.

But the basis of the architectural design of metal fireplaces is still the shape of the hoods and the methods of attaching them to the ceiling.

For so long the existence of fireplaces, including their metal structures, arose a large number of the most interesting forms. You can see hanging chimneys with a conical or pyramidal ending, and hanging bells-caps, and pipes 5-7 m high, which are attached to guy wires, and fireboxes suspended together with caps, etc.

Metal fireplace stove - is it necessary?

Metal light fireplaces and stoves can be found in Japan. Interesting design such a fireplace: a plane for the fireplace insert is mounted on a special support or stand, a steel cubic cap is connected to a chimney, which extends asymmetrically from the cap. Japanese fireplaces small size and are built against the wall. The chimney pipe is installed at a distance of 60 cm from the wall in accordance with fire safety requirements. The fuel is placed on the floor under the pipe, or it is combined with the firebox. Both the firebox and the floor under it must be lined with refractory bricks.

Of particular interest is a metal round mini-fireplace, which is mounted on a stand with a diameter equal to the diameter of the chimney pipe. The firebox of such a fireplace is very small, but there is enough fire in it to keep the room warm and you can admire it. In Japan you can often see heating stoves that look like our small cast iron stoves, but they are made of sheet metal and have an open fireplace insert.

What can such a fireplace be made from?

But still, wood-burning metal fireplaces, which are made from various building materials, are in great demand. For example, a lightweight steel cap harmonizes well with natural stone, With brickwork or with plaster. Appearance metal surface can be completely different - matte black or shiny, smooth or with a corrugated pattern, decorated with embossing, decorative stamps, and so on.

But still, wood-burning metal fireplaces, which are made from various building materials, are in great demand. For example, a lightweight steel cap harmonizes well with natural stone, With brickwork or with plaster. Appearance metal surface can be completely different - matte black or shiny, smooth or with a corrugated pattern, decorated with embossing, decorative stamps, and so on.

You can often find prefabricated fireplaces, the construction of which uses several materials. It can be brick, concrete, wood and metal. But this is not entirely correct. In any architectural composition, the use of several different materials leads to fragmentation of the composition. A pure architectural idea expressed by a single material is always used in all classic solutions.

It is strictly not recommended to combine different building and decorating materials in small fireplace, which is also installed in Not large room your house or apartment. In order to get interesting and modern design fireplace, two materials will be enough.

When building a metal fireplace, do not forget about its authenticity - the fireplace should look believable. If on brick wall if a cap that is too large is hung, secured by hidden consoles, then there will be a feeling of unnaturalness of the structure. A very large plane of obviously heavy riveted metal will not look natural on a thin, lightweight wall.

An ordinary metal fireplace will look dark, gloomy and angular without additional design inventions and solutions. But it can be easily turned into a light and elegant fireplace if you line it with light tiles.

Everyone knows that building a real brick fireplace– this and financial expenses, and time, and the services of professional stove-makers. But to tile it lightweight metal You can make a fireplace yourself.

Buy suitable model fireplace and Construction Materials It won’t be difficult to cover it, and then it’s up to you. Here you will get a double benefit in heating - the heat that the fireplace itself emits will be doubled by the heat from the heated tiles, which will ultimately allow you to get excellent comfortable heating of a cottage with an area of up to 40 m2 with a small thermal power of the device (8-10 kW).

Buy suitable model fireplace and Construction Materials It won’t be difficult to cover it, and then it’s up to you. Here you will get a double benefit in heating - the heat that the fireplace itself emits will be doubled by the heat from the heated tiles, which will ultimately allow you to get excellent comfortable heating of a cottage with an area of up to 40 m2 with a small thermal power of the device (8-10 kW).

A metal fireplace does not need to be decorated with tiles. Suitable for this regular tiles, and its possibilities in terms of decor diversity are even greater. Tiled cladding consists of two shells: a load-bearing layer made of aerated concrete 50 mm thick (laid on cement glue), and a decorative shell made of tiles.

How and with what to clad a wood-burning fireplace made of metal

The tiles must be fixed to aerated concrete wall on cement adhesive, which gives high bond strength even in the presence of large voids. It is first necessary to moisten the boards with water to slow down the hardening process of the adhesive composition. This is necessary so that the glue does not crack if it dries too quickly.

In order to achieve the same size for all seams, special plastic crosses must be inserted between the tiles. Once the glue has hardened, they can be easily removed.

Aerated concrete slabs are connected to each other at the corners, just like tile. Aerated concrete is laid using a special aerated concrete adhesive, and the tiles are secured with ceramic tile adhesive. The masonry is completed with cornice tiles on each tier decorative cladding fireplace.

At the very top of the masonry there is a chimney. Grate for warm air they are inserted last, and you can choose any appearance and shape that suits the design of the fireplace. The seams between the tiles are rubbed with a special decorative putty of the same color. You can use not only a rubber spatula, but also a regular sponge, especially in hard to reach places. Then the entire tile must be wiped with a dry cloth.

Thus, the metal fireplace is made of three tiers. The fireplace itself is installed on a plinth made of aerated concrete, the height of the plinth for a standard fireplace is 210 mm, depth - 450 mm and width - 700 mm.

The fireplace is lined on the sides aerated concrete slabs 250 mm wide. This is the second layer of the sandwich. The top slabs must be attached to the transverse cornice. The third layer of the structure is made narrower and should end at a height of approximately 2 meters. It's just decorative design, without which, however, the fireplace will look like an unfinished, rough detail of the interior of the room.

The only drawback of such a metal fireplace-stove is that to store firewood you will need to have separate room, and even preparing a supply of wood for the winter will take up your time.

Almost all owners country houses dream of a big warm fireplace. A live fire in the room conveys an indescribable atmosphere of comfort. And a brick fireplace looks especially presentable and sophisticated. However, not every home has the opportunity to equip such heating unit. In addition, a stone fireplace often takes up a lot of space and requires special attention: regular cleaning of the firebox and chimney, stone care and polishing exterior finishing. But do not despair if it is impossible to install such a fireplace for some reason. A metal fireplace can be an excellent alternative to a brick one. And with its task - to warm you up on cold evenings and create comfortable environment indoors - it copes no worse.

Why should you choose a metal stove?

A metal fireplace stove is a very good alternative stone oven. In terms of heat transfer, it is in no way inferior and is quite capable of warming up one of the rooms. It all depends on the amount of firewood and the degree of preheating. Therefore, even on the coldest days, the stove will delight you with warmth and will not let anyone freeze. A metal fireplace can be made in the form of an elegant and noble design. It will easily fit into even the most sophisticated interior.

The metal stove is a Japanese invention. As you know, the inhabitants of the Land of the Rising Sun are distinguished by wisdom, practicality and pragmatism, but, nevertheless, they know a lot about the noble design of premises. All these qualities are reflected in a metal fireplace.

Among the advantages of such a fireplace are lightness of design and portability. It is easy to install, move, dismantle. It weighs significantly less stone structure and does not require a heavy, durable and expensive foundation.

Another advantage of the fireplace is the combination of simplicity in operation with high efficiency. You can heat it even with a small amount of wood. It takes little time and fuel to warm up, since the metal heats up tens of times faster than brick. And at the same time it gives off a lot of heat, so it’s definitely enough to keep you warm in winter.

Unpretentiousness is another important advantage. Iron fireplaces are quite easy to clean and they do not require any special care. It is enough to just clean them of soot, wet clean them and, if necessary, polish them regularly (for shine). For these purposes, you can use soda, citric acid. Of course, specialized stores also offer a wide range of fireplace care products.

Tip: Polishing with toothpaste will help eliminate severe darkening. It is better if it is bleaching.

A corner fireplace will be stylish and modern solution for interior. Creating it with your own hands is real. They will help in this endeavor step by step instructions. Let's look at the process in detail.

There are not many disadvantages to a metal structure. The main ones are the rapid cooling of the furnace after the end of the combustion process and a high fire hazard. When loading firewood, carelessly touching a hot fireplace with your hand can cause burns. Therefore, it is necessary to work with the fireplace only with thick gloves.

Features of the location of a metal fireplace

A metal fireplace can be placed almost anywhere in the room. If you have a special desire, you can even place it in the center. However, it is worth considering that this arrangement is extremely unfortunate in aesthetic terms and does not at all comply with fire safety rules. It is easy to hit and knock over. Then the fire will not be long in coming.

It is best to install an iron stove against a wall. It can be directly built into the wall. This will significantly save space in the room. The chimney will fit neatly against the wall, and the problem of bringing it outside will be successfully solved. In addition, this will avoid smoke in the room. However, the walls behind the fireplace will not be clean. They can easily become smoky and darken.

The fireplace can also be installed against the wall, retreating some distance. Space savings are also maintained. The fireplace can be easily moved from one wall to another, it is easier to light and clean, since it is movable. A fire barrier is added to the fireplace design. However, this will not avoid damage to the walls, darkening of the wallpaper and peeling paint.

Ultimately, the fireplace can be placed in the corner of the room. Recently, this arrangement has been considered especially stylish. It takes up little space; on the contrary, the room visually expands due to the smoothing of the corners, and the living space is not overloaded. Design solutions corner fireplaces can satisfy even the most ardent aesthetes. Corner fireplaces usually small sizes. They are more stable. They are easier to heat and clean. The chimney can be easily removed to the outside environment.

Tip: Do not install the fireplace near a window or door. Air sources do not have the best effect on the efficiency of the fireplace and fire safety.

Materials for making a metal fireplace with your own hands

An iron fireplace is quite simple to make. It does not require any special material costs. To assemble such a fireplace you will need:

- metal sheets 3-5 mm thick (for the firebox);

- metal sheets 0.5 mm thick (for the ash pan);

- grate or reinforcing bars;

- firebox door made of cast iron or fire-resistant glass;

- door hinges;

- metal slats with a diameter of 5 cm (for legs);

- several (4-5) full chipboard sheets or other materials for the pedestal (for example, brick or cement board);

- basalt wool;

- cement mortar;

- chimney pipes with a diameter of at least 20 cm, if necessary, an elbow for the outlet and connection of several pipes;

- bracket;

- head;

- fungus;

- heat-resistant sealant;

- building level;

- yardstick;

- Bulgarian;

- welding;

- screwdriver.

Iron stove installation diagram

Before you begin directly assembling the fireplace, you need to develop and carefully study the drawing. Finished drawing can be found on the Internet on numerous construction sites and forums. But it’s best to create an individual scheme using it as a basis. In this case, it is necessary not only to draw on it the fireplace itself and its component parts, but also to indicate the dimensions of the stove, and also to draw up a detailed assembly algorithm in the drawing (in the form of numbers or arrows). You should start with the pedestal and end with the outlet of the chimney to the street.

Tip: When drawing up a drawing, take into account the specific layout of the room, interfloor ceilings, floor and ceiling.

The main stages of making a fireplace with your own hands

Making a metal fireplace is no more difficult than a regular potbelly stove. If you draw up a competent drawing and follow all the technology, even a beginner can cope with this task.

- An iron fireplace gets quite hot. Therefore, installing a fireplace begins with preparing the floor surface. If the floor is wooden, then between the ceiling and floor covering it is recommended to put a layer basalt wool for thermal insulation.

- Next you need to prepare the pedestal. It can be made by connecting several sheets of chipboard together, with a fire-resistant coating (fibre cement board) placed on top.

- If the walls of the room are covered with wallpaper or decorated with other materials susceptible to fire, then it is better to protect them in the area where the fireplace is located ceramic tiles, brickwork or artificial stone.

- After preparing the room, assembly of the fireplace begins. The fireplace design is simple. First you need to connect the side walls of the furnace together by welding. It is welded to them back wall and the front wall, in which it is first necessary to cut a hole for loading firewood (in the middle) and at the bottom in the ash box for cleaning out the ash.

- A thick iron sheet is welded to them - the bottom of the fireplace. Before installing the bottom, you need to attach the legs to it. Optimal height legs - 10-12 cm, and their thickness is at least 5-7. The oven must be stable. Therefore, the width and number of legs are determined by the weight of the stove. Thus, you should get a metal case.

- After this, partitions are installed for the ash chamber and combustion chamber. It is better to make the combustion chamber two-layer (a separate body inside the fireplace) - separate it from the walls of the stove.

- A grate must be installed between the firebox and the ash pan. You can buy it ready-made or weld it from reinforcing bars.

- Hinges are welded to the main part of the furnace. And doors are attached to them. It is necessary to weld the corners 10-12 cm below the firebox door. They serve as the basis for the grate.

- The fireplace is closed with an upper wall-lid. If a hole for the chimney is not provided, it must be cut before installation.

- The last thing you need to do is install the chimney.

Read the article about on the hiring site.

Tip: After completing each assembly step, check the design using building level. If there are gaps in the oven, then most likely the parts are not connected smoothly. The oven will have to be reassembled.

Chimney device for an iron fireplace

Chimney - component fireplace designs designed to remove combustion products, in particular smoke, to the outside. No fireplace is complete without it. Chimney for iron stove is a long pipe (or several pipes connected in series). The chimney must go through the roof to the street. It can be straight - one pipe is directed vertically up to the exit to the roof, or it can be two or three elbows, i.e. come out in a zigzag pattern.

The chimney is installed in a special hole on the upper surface of the fireplace and, using a bracket, is parallel near the wall (with support on it) to the roof. If you have to make bends and use several pipes to bring out the chimney, then they are connected to each other using elbows. All joints and penetrations must be treated with heat-resistant sealant. For thermal insulation, you can use basalt wool.

Ultimately, it is necessary to bring the chimney to the roof. It should rise above it by at least 500 mm. A head and a fungus are placed on top of the pipe. They will protect against water and snow getting into the chimney.

This completes the furnace manufacturing process. If desired, it can be supplemented with decorative items - cast figurines, gilding and or silver spray paint. It is better to refrain from painting the fireplace, as the paint may begin to melt or crumble, which undoubtedly spoils the appearance of the fireplace.

Tip: A metal fireplace can be decorated with monograms and patterns. This will turn a nondescript stove into a noble piece of furniture.

Rules for the operation and care of an iron hearth

In order for an iron fireplace to serve for a long time, it needs proper care. Once every 2 weeks it is necessary to clean the stove: remove remaining ash from the ash pan, clean the firebox of soot and regularly clean the chimney. Only dry cleaning is allowed. A metal fireplace is easily corroded, so it is strictly forbidden to wash it with water. But with a damp cloth you can clean the glass doors and the surface of the chimney pipes from dust.

Compliance with operating rules is no less important. After assembling the fireplace, you need to wait about a month before starting to light it. During this time it will dry out properly, excess moisture will evaporate and the sealant will adhere firmly. It is important to choose and correct view fuel. It's mostly firewood. The most the best firewood- from birch. It gives off 20% more heat than other tree species. You can also use coniferous species - pine, spruce, larch. They will give the surrounding air a subtle aroma of pine needles. Fuel can be not only wood, but also pellets and ethanol.

Regular cleaning of the fireplace will extend its lifespan

When operating a fireplace, it is extremely important to follow fire safety precautions. To make using a fireplace comfortable, you need to remember a few rules:

- do not install a fireplace in an active living area: bedroom, middle of the room, kitchen. It's easy to knock over. The best place for a fireplace in a corner or near the far wall;

- do not install the fireplace near flammable materials, furniture and windows;

- do not leave the fireplace unattended;

- keep small children away from the working fireplace;

- do not use varnishes, paper products or fabric when decorating the fireplace;

- do not forget to protect the fireplace from wooden walls and gender;

- Do not store flammable liquids near the fireplace.

By observing these simple rules, you can be sure that the fireplace will serve you faithfully for a long time and will warm your home for decades!

A classic example of a fireplace is a wood-burning one. These are the products that have been used since ancient times. Certainly, modern models They are somewhat different from the first ones, but the concept remains the same, only the shell and decoration changes. Modern fireplace can both heat the room and create a certain atmosphere that no other device can do.

About efficiency

The productivity of such fireplaces, frankly speaking, is very small: about twenty percent. Therefore, wood-burning products are more suitable for decorating a room and creating psychological comfort than for heating.

Of course, if an esthete needs such a fireplace, then no level of efficiency will become a hindrance. Wood burning fireplace will allow you to watch the blazing flame, enjoy listening to the characteristic crackling of burning wood and feeling a special aroma. Long-term winter evenings, observing such a picture, say, over a cup of hot tea or a glass of good wine.

Varieties

Metal wood-burning fireplaces can be divided into two types:

- closed – the firebox is closed with special glass that is resistant to high temperatures, which allows you to increase the productivity and security of the solution;

- open - an open firebox is used.

The photo clearly shows the difference between these species.

A wood-burning metal fireplace allows you to... different colors flame. For getting blue flame You can use aspen logs. Since from coniferous species A lot of soot is formed; they are not used as fuel for metal fireplace stoves. And birch trees have high heat transfer, so with their help it is easier to warm up the room.

To save free space, sometimes the product is made angular.

If we talk about the types of metal fireplace stoves, then cast iron samples are very often used. They are quite mobile, compact and have an attractive appearance.

About design features

A metal fireplace stove can be wall-mounted, built-in, wall-mounted, central or corner.

Such fireplaces have a lot of advantages:

- high efficiency;

- fast heating;

- can be installed anywhere in the room;

- ease of maintenance;

- light weight;

- prevent the formation of fungus.

At the same time, accidentally touching metal parts, you can easily get burned, so you need to use it very carefully. The stove cools quickly enough, the heat is distributed unevenly, and a chimney is used.

The product is most often used in country houses, at the dachas. If this is a biofuel model, then it can be installed in an apartment without any problems.

If the product is complemented temperature sensors economizer and other elements, heating of a higher quality is obtained.

Make a metal fireplace with your own hands - not an easy task, which requires some experience, as well as taking into account certain points. In order for the result to be predictable, you must first prepare a drawing, as in the photo.

- First, the location where installation of the product is necessary and relevant is determined. It is recommended to select it near the end wall. The angle between the walls is also a way out. You should not choose a place near a window, as this can cause drafts in the room if the windows are not airtight enough.

- Once the location has been determined, calculations must be made. The dimensions of the structure are most often determined by the area of the existing room where the fireplace will be located. The ratio of height and width is 2 to 3. The diameter of the hole for the firebox is half its height. If you change these proportions, you can either create smoke in the room or reduce heat transfer.

- For manufacturing, sheet metal of 0.5 mm (ash pan) and 3-5 mm (fuel pit and chimney exhaust) is used. Stands, fasteners and door are cast iron, pipes and elbows are stainless steel.

- The firebox can be made wide, but not deep. To increase heat transfer, its walls must expand towards the room. This can be seen in the photo.

- A smoke hole is made less area fireboxes from eight to fifteen times.

- Typically, the height of the pipe is about four meters.

- If you already have a ready-made chimney, then the type of wood-burning metal fireplace should be selected as simple as possible, for example, using ready-made cassettes as a firebox.

- Insulation – important question. It is necessary to insulate the walls located near the fireplace, as well as protect the joints of the chimney with ceilings and other elements.

- You shouldn’t count on high draft in such a device, so you need to build a storage shaft with your own hands that accumulates smoke, from which it will then go out into the street through a pipe.

- A gas threshold is a must in the interior of the fireplace. It will allow you to protect yourself from pressure changes and the formation of sparks. This threshold can be made wider than the chimney by one or two centimeters.

- To extinguish sparks, a grid should be provided, and forged tools should also be provided.

- It is clear that many DIY elements in normal conditions impossible to manufacture. Therefore, they need to be ordered from a specialist, providing clear drawings indicating the dimensions and materials used.

Turning to professionals is an alternative solution

If you can’t make it yourself, the video instructions don’t help, or you don’t want to do it, then you should turn to specialists. Thanks to experience, it will be much easier and faster for them to build such a metal fireplace design.

When thinking about setting up their country home, many people think about installing a fireplace. After reading the manual for making fireplaces, you come to the conclusion that it is impossible to build one in your home. It will take up a lot of space. Or maybe yours country house stands on bad soil and foundation for brick oven impossible to do. But I want comfort and live fire. Then you decide to find Alternative option, which is easy to do with your own hands.

Iron corner fireplaceHow can I replace a brick oven?

A metal device can be an equivalent replacement. For such a stove there is no need for a foundation at all. Its weight is light. For such a stove device, the task is not to heat the entire house. It is enough that it will create a special atmosphere. But the warmth that comes from it is real. You won't freeze on cold evenings. They say that the tradition of using such fireplaces came to us from the Land of the Rising Sun - Japan.

Such devices are made from various metal: copper, steel, tin. It turns out there are many styles of metal stoves. Various shape caps, various chimney fastenings provide huge variety forms of metal devices. This one can be used on its own or can be made with stone, ceramic or tile.

Installation location

Like any stove device, an iron fireplace must be installed in a sufficiently large room. For uninterrupted operation the unit constantly requires air supply. If the stove structure is not heated, then it can be used as a hood.

The weight of a metal fireplace is many times less than that of a brick one. But still more than 100 kilograms. If you place it on a wooden floor, the floorboards may not support it. Therefore, it is recommended to strengthen the location of the furnace structure.

Stand

The installation of a fireplace must begin with the stand on which it will stand.

The stand can be either purchased or made. Well, I understand about “buy”, I went and bought it. But you can make a stand with your own hands from iron corners. Trim the corners and make a rectangle out of them. Screw the legs of the rectangle to the floor boards all the way through. Weld on top a metal sheet. In a word, the idea is this: a metal stove device should stand on a stand and the space around it should be fireproof.

Fire insulation

All chimney passages through the floors of the house must be insulated. Fire insulation must also be present on the wall near which the metal fireplace is located and where the chimney is attached.

Flaws

To the disadvantages metal device It can be attributed to the fact that it cools down quickly and therefore it constantly needs to be supplied with fuel.

This stove design can be placed anywhere

This stove design can be placed anywhere Advantages

But the advantages include the fact that such a stove can be installed in any building or room.

Metal fireplaces can be lined with brick. It's easy to do it yourself. In this case, the brick is placed with a small gap, since the iron firebox will expand when heated. These fireplaces retain heat longer.

Fuel

If we talk about wood fuel for such structures, then heat better with firewood deciduous trees. Coniferous firewood releases resin, which when burned contaminates the fireplace. And here coal You cannot light a metal fireplace.

Firebox

Made from iron sheet. It should be divided into two parts, namely a firewood combustion chamber and a smoke chamber. These chambers are separated by a damper, which saves heat when closed. You can weld such a firebox with your own hands, or you can purchase a ready-made one.

If you build an iron fireplace, you need to take into account that it has double walls. This design allows the cold air from the metal firebox to heat up. Therefore, if you cook with your own hands, be sure to take this into account.

Iron firebox

Iron firebox Chimney

You can make a chimney for a fireplace with your own hands. For this we need chimneys stainless steel and elbow. We assemble a chimney from them. Manufacturing is carried out by connecting pipes to each other using sockets. We secure the pipes together using mastic, which is used for laying tiles. One end of the pipe is coated with mastic and inserted into the other end of the pipe. The knee is used if necessary. The pipe is secured with wire to brackets in the wall. The pipe goes into the attic, where it is placed in thermal insulation. Wrapped with glass wool, then metal mesh and a tin casing is put on top. On the roof, caps are placed on the pipes. The entire chimney, which runs through the room, is also covered with a casing.

This is currently the case metal constructions are called fireplaces, and before that they were the most simple shapes were called potbelly stoves. This stove will fit perfectly into the interior of your country house. You won't have to worry about long installation times. It can be decorated with a mantelpiece, with all the attributes inherent in a real brick building. The flames in the firebox will also blink and the wood will crackle merrily. You will not regret if you install such a fireplace.