Today there is a large number of roofing materials. Each of them has its own pros and cons. One of the most popular roofing materials is metal tiles.

Today there is a large number of roofing materials. Each of them has its own pros and cons. One of the most popular roofing materials is metal tiles.

A roof made of this material is not afraid of temperature changes, and its installation can be carried out in any climatic conditions. Metal roofing is resistant to mechanical damage.

If necessary, the sheet of roofing material can be easily tinted or replaced with a new one. The rest of the article will discuss the main types of metal roofing tiles.

The following materials are used for the manufacture of metal tiles:

- Steel sheet. Galvanized steel is most often used as the base of metal tiles. In this case, the sheet thickness is 0.45-0.55 (rarely up to 0.6) mm. A zinc coating is used to protect the metal from corrosion. Also, steel coated with aluminum-zinc can be used as a base. Metal tiles coated with aluminum zinc are more durable, but also cost much more.

- Aluminum sheet. The advantage of this material is that it does not need to be protected from corrosion. But still, aluminum metal tiles have an additional coating that increases the service life and increases the strength of the roofing material. It should be noted that aluminum metal tiles are lightweight. The disadvantages of this material include high cost and a rather poor palette of shades.

- Copper sheet. Copper metal tiles look very elegant and noble. No protective polymer coatings are used, since the patina perfectly protects from adverse influences. Copper metal tiles are used very rarely and have a high cost.

Copper metal tiles

Types of profiling

Today there are many profiles of metal tiles. The following article will list the most common ones.

Profile "Monterrey"

This roofing material is very similar to clay tiles, which is why it has become very popular. Monterrey tiles are an aesthetic, easy-to-install material that is well protected from natural influences.

Sheets of this material are made from high-strength steel, protected by a polymer layer. The Monterrey profile is perfect for roofing residential buildings. It should also be noted that the Monterrey metal tile profile has a smooth curve. The edge of the roof has the form of steps, located symmetrically or asymmetrically.

Sheets of this material will hold several layers. A protective coating is applied to both sides of the sheet. polymer coating. Each layer of metal tiles has its own function:

- Inner layer. This is a sheet of galvanized steel that takes on the main external load.

- Galvanized (zinc-alumina) layer. It is applied on both sides of the profile and protects the metal from corrosion.

- Primer layer. Apply on both sides of the sheet. This layer has high adhesion. Due to this layer, the paint adheres securely to the surface of the sheet.

- Polymer layer. Applied on the front side of the material. The service life of the metal tile depends on the quality of this layer.

- Varnish layer. Apply to inner side leaf. This layer provides additional protection.

Profile "Cascade"

This type of roof looks like a chocolate bar. The advantage of Cascade metal tiles is their low cost.

A distinctive feature of this material is the severity of its rectangular outline. Therefore, such metal tiles are good to use for roofs that have a complex shape. The Cascade profile looks neat, strict and proportional.

Profile "Joker"

The main difference between Joker metal tiles and the most popular profiles (for example, Monterrey) is the smaller number of waves. Monterrey tiles have seven waves, while Joker has six.

Moreover, the materials have almost the same width. Due to this, the Joker metal tile looks smoother and more convex. A roof made of this material looks soft and textured.

This roofing material is perfect for public buildings, private houses, trade pavilions and industrial buildings.

Joker metal tiles are made from high quality galvanized steel, protected by a polymer composition.

Profile "Banga"

The profile of this material has a rounded rowing shape and a flat sole. Banga tiles are different from other types of tiles greater height profile.

This property gives Banga metal tile roofing architectural expressiveness and exclusivity. Therefore, it is often used as a roofing covering for luxury country cottages. This material can be laid on roofs with a slope angle of 14 degrees. Banga metal tiles are resistant to heavy snow loads because they have a high profile height.

Profile "Andalusia"

This type of metal roof tile appeared on the domestic market quite recently. main feature metal tiles of Andalusia - a method of attaching sheets to each other and to the sheathing. There is a Z-shaped lock at the bottom of the roofing sheet. This ensures a tight fit of the sheets to each other.

The coating of the sheets can be matte or glossy. It is made from polyester, pural and other materials. This tile has many shades.

Andalusia metal tiles are made from galvanized steel. Several layers of primer and polymers are applied to the metal. These layers provide protection against corrosion, moisture and ultraviolet radiation.

Andalusia tiles have the following advantages:

- There is no need to purchase screws to match the color of the roofing;

- Externally it looks like natural tiles;

- Long service life;

- The sheet fastening system is quite simple, so even a non-professional can perform the installation;

- After installing Andalusia metal tiles, a sealed roofing covering is formed, on which there are no through fastenings.

Profile "Shanghai"

This metal tile began to be manufactured in Russia quite recently. It has a high symmetrical profile. It should be noted that the equipment used to produce Shanghai metal tiles can be used for the production of corrugated sheets. To do this, it is necessary to distinguish the stamping device on the line.

This metal tile has many positive qualities. The main advantages include:

- Ease of installation;

- Strength and long term services;

- Attractive appearance.

Shanghai metal tiles have an original profile geometry. This type of metal roofing tile looks great on almost any building because it has a high profile. Thanks to the symmetry of the pattern, this tile looks elegant and strict.

The basis of this coating is polyester. The material has long been used in the production of metal tiles, has a glossy appearance and is distinguished by its plasticity and high color stability.

Metal tile coating made of polyester, shiny, smooth, relatively inexpensive. It is highly resistant to corrosion and ultraviolet rays, that is, it will not fade for a long time under the sun. However, in thin layers (up to 30 microns) it is damaged by light mechanical influences, for example, when layers of snow fall off the roof. You should not use polyester where weather unfavorable.

- Matte polyester (PEMA)

Among types of metal tile coverings Matte polyester looks the most attractive. It is polyester with Teflon added to create a matte finish. In addition to resistance to UV rays, it also has increased resistance to mechanical damage due to the increased coating thickness (35 microns). It will last a long time even in difficult weather conditions.

- Pural (PU)

Metal tiles with pural coating It is based on polyurethane, the molecules of which are modified with polyamide. The thickness of the coating is 50 microns, which gives it additional mechanical stability. Ultraviolet radiation and even chemically aggressive substances, such as acids that fall with precipitation in areas with polluted air, do not change the properties metal tiles with pural coating. She serves long time without color change and mechanical resistance in any conditions.

The surface of such metal tiles is silky to the touch and matte in appearance. Thanks to the properties of pural, roofing with such a coating is easy to process and install. The temperatures at which it retains its properties are from minus 150 to plus 1200 degrees Celsius.

- Plastisol (PVC)

Plastisol 200 - metal tile covering made of polymer 200 microns thick. It is distinguished by volumetric embossing imitating leather or tree bark. Developed specifically for difficult climatic conditions, including industrial areas with high level pollution environment.

Plastisol 100 has half the thickness and is used mainly indoors. It is also produced with coating on both sides and is used for the manufacture of spillways.

- Polydifluorite (PVDF, PVDF2)

Of all kinds metal tile coverings this is the most suitable for decorating facades. It consists of a mixture of polyvinyl fluoride and acrylic in a ratio of 4:1. Contains high quality pigments to impart shine and color that is resistant to long-term exposure to ultraviolet radiation.

The polymer is quite hard, has hydrophobic properties, which allows it to “repel” dirt, while being quite plastic. It can be either matte or glossy. Metal tile coating can be shiny like metal. To do this, the top is coated with varnish with the addition of a special dye. Resistant to atmospheric influences and corrosion.

Comparison of characteristics of metal tile coatings

In this article:

Metal tiles are a modern roofing material for pitched roofs with a slope of at least 12 degrees. The spectacular imitation of a tile covering, the reliability of metal and the increased wear resistance of decorative and protective coatings, which are not afraid of snowy winters and do not fade under the sun, have ensured the popularity and steadily growing demand for this type of roofing. Every year about 100 million square meters of metal tiles are sold on the Russian market.

Is there a classification of metal tiles, and what types of this coating are most popular among our compatriots? Let's try to figure it out.

Metal tiles are different:

- by the thickness of the raw material;

- according to the form of profiling;

- wave height and step width;

- by type of decorative coating.

Types of raw materials

Galvanized (alumina) steel with a thickness of 0.35-0.7 mm is used, on which additional decorative coating, providing high strength and anti-corrosion protection roofs. In cross-section, a sheet of metal tile looks like this (Fig. 1)

The generally accepted standard for the thickness of the blank sheet is 0.5 mm, but it is observed only by European manufacturers, since according to ISO standards the possible deviation does not exceed 0.1 mm. Our GOST standards are more flexible, and the thickness of the metal can be either 0.45 or 0.5 mm, and at the same time “fit” into the standard.

Geometry, color and design

Highlight different kinds metal tiles depending on the color palette, profile type and geometric dimensions. The choice of metal tile color depends entirely on the individual aesthetic preferences of the developer; the service life and quality of the material are not affected by the shade (although many believe that bright colors fade faster, in practice - it depends only on the quality of the coating). Color palette– from 20 to 40 shades, depending on the brand of raw materials. According to manufacturing and trading companies, the most popular color among our compatriots is dark red burgundy.

For metal tiles, maximum dimensional accuracy is important (length, width, sheet height, profile shape and metal thickness), not only the quality, but also the installation of the roof depends on these parameters (often the same type of metal tile depends on different manufacturers“does not fit together” when laying).

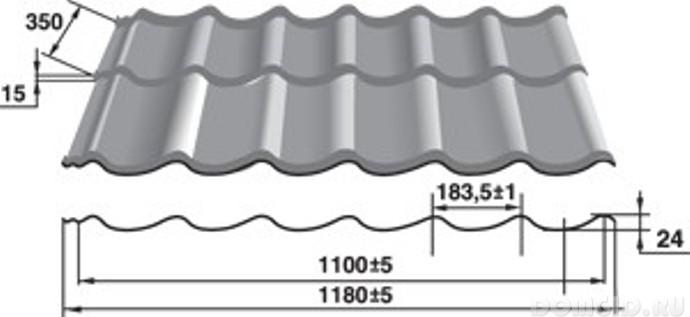

Most popular geometric parameters different types metal tiles are shown in Fig. 2.

The rigidity of the sheet depends on the height of the wave (depth of the stamp). The higher the relief, the less flexible the metal tile.

There are two dimensional forms:

- up to 50 mm – “small” wave;

- over 50 mm – “high”.

The profile pattern can be either symmetrical or asymmetrical.

The most popular types (profiles) of metal tiles

The undisputed leader of the Russian market (78%) is metal tiles “Monterrey” and its subtypes: “Standard”, “Modern”, “Maxi”, “Super”, “Retro”, “Lux”, “Classic”, with various forms and parameters, but with the same rounded smooth waves of profile and steps.

Cascade (12% of the market) - has rectilinear shapes reminiscent of a chocolate bar, allowing this type of metal tile to be used for quick roofing of large areas.

Andalusia (7.3%) - the appearance most reliably imitates natural classic tiles, and internal fastenings allow you to hide the joints, making the roof covering look like one whole, without visible transitions.

Less popular profiles are “Spanish Dune”, “Banga”, “Pamir”, “Shanghai”, etc.

Decorative and protective coating

External covering– one of the most important indicators of the quality of metal tiles. If the type of wave, sheet dimensions and profile geometry depend on the configuration production line manufacturer, then the composition of the decorative protective coating is the same for all manufacturers.

On offer Various types coatings, thickness from 0.02 to 0.25 mm:

1) Polyester(glossy polyester) is the most popular and inexpensive coating with excellent resistance to corrosion and UV radiation. But the thickness of the layer (25-30 microns) is easily damaged when snow melts and does not provide protection against mechanical damage, therefore it is not recommended for use in regions with difficult weather conditions;

2) Matte polyester– a thicker layer (from 35 microns) increases resistance to damage, and, accordingly, increases the scope of application. Disadvantage: small color range;

3) Pural– one of the highest quality coatings (thickness 50 microns), made on the basis of polyurethane, suitable for aggressive environments, has high resistance to temperature changes, but less strength than plastisol;

4) Plastisol– beautiful textured coating, with an embossed surface based on PVC. Thanks to its thickness of 200 microns, it is recognized as the most resistant to damage and weathering. But in practice it has shown low resistance to direct UV radiation, in addition, in a number of countries due to the PVC composition, this coating is recognized as environmentally unsafe;

5) Polydifluorite(PVF) - the most flexible polymer coating (80% polyvinyl fluoride, 20% acrylic), despite the small layer thickness (up to 30 microns), provides reliable resistance to any damage, has a wide range of colors, but also the highest cost.

The quality of the protective coating determines the rigidity of the sheet, strength, anti-corrosion and performance properties of the roof, the warranty period and the price of metal tiles.

Today, metal tiles are on the list of the most purchased roofing coverings. Thanks to its appearance, any building acquires an aesthetic appearance, and imitation natural tiles increases the status of owners in the eyes of guests. In addition to its beauty, this product has high waterproofing properties and a long service life. In this article I will talk about popular types of metal roof tiles, with photos and their names.

Advantages and disadvantages of metal tiles

Whatever high quality the roofing material did not have, it will have its drawbacks. They can be related both to the raw materials of the product and to the region of your residence. So, let's look at the advantages of metal tiles.

- The dimensions of the sheets can be selected individually, which will create fewer seams on the roofing surface. This will significantly increase its waterproofing and strength characteristics.

- Maintenance of such a roof does not amount to special labor. If the installation work was carried out by responsible people, then preventive examinations can be reduced to a minimum and only check the attachment points. Of course, over time the sealant may deteriorate, but for the first 5-10 years you have nothing to worry about.

- The roofing sheet is lightweight, so you do not have to create a reinforced rafter system. As for the sheathing, it can be loose, the main thing is that the waves of the sheet fall on the boards. Thanks to this, you will save quite a lot of money.

- The metal tile sheet has large dimensions, so it is very easy to install the roof, but despite this, it is better to use the service of a partner so that the work goes faster.

Now, let's move on to the cons.

- The thinness of the material plays a cruel joke on it. Incorrectly selected sheets with low rigidity can break in half if colossal loads occur.

- The sound insulation of metal tiles is very low. When it rains, you will hear a knocking sound that is amplified by the echo attic space. This problem can be solved by installing a thermal insulation layer, but this will roofing pie more expensive.

- When installing the roofing sheet, it is very important to wear special shoes that will not scratch the surface. The fact is that the protective layer is very thin and the slightest wrong touch can leave a scratch through which moisture will enter the metal and, as a result, corrosion will occur.

- The more complex the roof frame, the more waste will remain. A rigid sheet of metal cannot be bent in any way, therefore, it has to be cut. In some cases the amount of waste can exceed 30%.

- Metal coatings tend to collect large amounts of condensation, so to protect the roofing pie from moisture you will have to purchase additional insulating materials, protective impregnations for wood, etc.

- Due to their shape, some types of metal tiles experience some difficulty in draining precipitation into winter time. This is most often observed on low-slope structures.

As you can see, there are just as many positives in this material as there are negatives, so you will have to think through everything carefully, and only then purchase the roofing sheet.

Raw materials for the production of metal tiles

To date this coating made from three metals, namely:

- Become

- Aluminum

Galvanized steel makes the material cheaper, since aluminum and copper are non-ferrous metals. Sheet thickness in in this case is in the range from 0.45 to 0.55 millimeters. As you may have guessed, the zinc admixture makes the product more resistant to corrosion. Several layers are applied on top of rolled steel to make it stronger. These include polymer protection, which we will talk about a little later. In addition to pure zinc, an admixture of aluminum is often added to the material, which increases the service life, but the price tag also increases.

Aluminum as a raw material is ideal solution problems associated with corrosion. This metal is a high-alloy metal, so it has nothing to fear.

As a result, this metal tile has high strength and durability. In addition, the weight of the sheet is so light that you do not need a partner for installation work; all procedures can be carried out independently. The only drawback is the scarcity color solutions and high price.

As for copper, all the disadvantages of the above metals do not affect it. Such a roof looks very noble from the very beginning, and over the years it gains strength, and not vice versa. Thanks to the patina that appears on copper, it becomes more resistant to precipitation and other weather conditions. The shelf life of such material exceeds 200 years. The price for such metal tiles will be very high, but if you look at the operation, it becomes clear what you have to pay for.

Types of metal roofing tiles. Photo and price

Now I want to show and tell a little about the already well-known Monterrey, Cascade, Joker and Banga. All developers liked these types of metal tiles at first sight and are still in great demand. As for new products, there are more and more of them every year, but not all coatings are worthy of attention. From the number modern species metal tiles, I would like to highlight Andalusia and Shanghai.

Monterrey

The country of origin of this coating is Finland. The surface of the sheet stands out for its extreme similarity to natural tiles, which actually influenced its popularity. This metal tile has a small mass and, as you might guess, is very aesthetic. Concerning installation work, then at all stages there will be no problems with it. It is a pleasure to operate such a roof, because it is unpretentious in maintenance and with the correct slope roof slope, sediment will be removed naturally.

Cascade

Most of the guests who drop by will make fun of you and ask: “why did you pour chocolate on the roof?” The similarity of the sheets of this metal tile with a chocolate bar is obvious. The cascade stands out for its strict proportions and sharp edges, which allows for more comfortable covering roof frames complex shape. A building covered with such a roof will acquire strict outlines, unique proportions and neatness. If we consider this variety from a different point of view, we can say that it is classic look, which will always be relevant.

Joker

A distinctive feature of this material is the rounded ridge and sole. Such waves on the sheet create a more faithful imitation of natural tiles, but with their own attractiveness. Joker combines the elegance of classic and modern, so if you love such styles, then you will surely like it.

Banga

The last most popular type of metal tile is produced under the name “Banga”. Despite the fact that it began to be produced relatively long ago, it is still considered a new product. The leaf profile of Banga has interesting ornate shapes, which is why most developers fell in love with it. The ideally arranged shape of the sheet allows you to create some convex image. The only drawback is the small width of the sheet, due to which you have to spend more time on installation work.

Andalusia

So I really got to modern varieties metal tiles. Andalusia has become a very popular product in our country in a very short time. Used for sheet production special equipment from Europe, so the quality of this coating is excellent. As for installation work, in this case it can take place along a different channel. Invisible fasteners make this type popular, because even the most popular materials are fastened from the outside. Thanks to the snap locks under the roofing sheet, the surface is extremely waterproof and aesthetically pleasing.

Shanghai

The name of this type of metal tile speaks for itself, because it was produced in China. This product has existed in this country for quite a long time, but Russia only learned about it a couple of years ago. A striking feature of the appearance is the very high profile, which measures 66 millimeters and is symmetrical.

All of the above types of metal roof tiles are very popular, and all developers should know about them, at least distinguish them from the photo. Now, let's look at the types of protective coatings that make it easier for metal to withstand all the hardships of weather conditions.

Types of protective coatings for metal tiles

Understanding which protective layer is better than another, you can only purchase quality materials. Just a few decades ago, construction did not have such capabilities; it was necessary to use products with a low degree of protection, which fell apart right before our eyes. Today there is no such problem, but along with the abundance of materials, the problem of choice has arisen.

Polyester with glossy surface

Products with this type of coating are marked PE. By the way, it is used quite often, out of ten various materials you'll find glossy polyester on seven. This protective layer can be applied not only to metal tiles, but also to some types of corrugated sheets. Its low cost makes the products more accessible to ordinary developers, which is why it is so popular. The only drawback is the low service life, which in exceptional cases reaches 10 years. Based on this we can say that metal sheets, the coating with this protection will not last as long as it could. In addition, the protective layer reacts extremely poorly to negative temperatures; it is better to lay such metal tiles in temperate latitudes, where winters are not as harsh as in the north.

Matte polyester

Find a product covered like this protective composition can be used by the following abbreviations: MPE, Matpol and PEMA. In order for the material to look slightly different, the developers added a certain amount of Teflon to the composition, due to which it suffered enormous changes. The shiny surface became matte, and the stability increased several times; now a sheet coated with such polyester can last more than 20 years. But the negative aspects were never removed, and they remained.

Pural with high strength

This protective layer is based on the well-known polyurethane, which protects the surface of the sheet from harmful effects. ultraviolet radiation. Due to its high strength, the composition applied to the surface is much more difficult to damage and is not afraid of chemical reagents. The temperature range is large, so the material can be installed in any region of Russia. As for the duration of operation, it is 25-30 years. The negative point is the inflated price tag.

Pural with matte surface

There are quite a few markings for this layer and the most commonly used ones are: MPURA and PUMA. In terms of application, it is no different from the previous product. The composition was invented by the Ruukki company from Finland, so there is nothing to say about the quality, it is excellent. This coating looks very beautiful on metal tiles. Thanks to correctly selected components, the layer has some plasticity, which significantly affects the service life. The warranty is provided by the manufacturer itself and is about 30-40 years.

Polyurethate layer

This type of protection is called Prisma. It was produced in England at the Corus plant. The composition includes polyurethane itself and an alloy called Galvalloy. It contains the vast majority of aluminum and some zinc. This coating can protect a sheet of metal for 15 years.

Plastisol with PVC impurities

This mixture, as practice shows, has won the trust of developers in warm countries, but is completely unsuitable for use in the north. The fact is that the acceptable temperature range is from +10 to +60 degrees. By covering the metal with such a layer it becomes similar to birch bark or skin. Apply on public buildings metal tiles with this type of protective coating are highly not recommended, as they will quickly fail.

PVDF protection

By covering the sheet with such a mixture, manufacturers make it refined. It protects the metal well from corrosion and withstands all weather conditions. The temperature range is practically unlimited, so such metal tiles can be used anywhere.

Composite layer

If all the above types protective layers had only one layer, here there are two. The first of them is quartz sand, and the second is a polyester fill. Thanks to sand, this coating is very resistant to mechanical damage. The surface is matte and the sound insulation properties are high.

One of the first places in the ranking of the most popular roofing materials is occupied by metal tiles. It is not without reason that she is in such a high place in the ranking. Choosing it as a material for roofing in own home, the owner will be convinced of the sufficient strength of the material and its immunity to natural phenomena, will be surprised large selection of the proposed colors, he will be able to try to install it with his own hands and make sure of the ease of installation, low weight and long service life. Metal tiles are a material that will look ideal on the roof of a bathhouse, a cottage, and any country buildings.

What is metal tile

Metal tiles are one of the most popular roofing materials of our time. It is made as follows: on a so-called base made of metal profile, apply several protective layers of polymer materials. Namely - on sheet steel a layer of zinc, then a passivating layer, a layer of primer on it and, last but not least, a colored polymer coating.

In the production of metal tiles, sheet aluminum, galvanized iron or copper are most often used as a base.

With its external outline, this material is very similar to ordinary tiles made of clay. But unlike roofs made of natural tiles, roofing felt or slate, a metal roof has a neater appearance, which compares favorably with the rest.

Due to the structural features, it will last up to 50 years without replacement. Of course, the duration of its service depends on the degree of exposure and aggressiveness of the environment and the quality of the polymer coatings used in the manufacture of tiles; depending on the materials used for the manufacture, prices for types of metal tiles are determined.

In order to be convinced of its strength, it is enough to know that sheets up to 0.5 cm thick can easily withstand the weight of an adult or a weight of snow up to 250 kg per sq. m.

Experts advise covering roofs with metal tiles, the slope of which is at least 14 degrees relative to the horizon.

Base material

As mentioned above, the basis for metal tiles is a sheet of metal. Today, several types of it are produced - using galvanized iron up to 0.5 cm thick, alloys of non-ferrous metals and aluminum as a base.

Basically, a material with a galvanized iron base is used to cover the roof, because it costs much less than other types produced today. Products with a base made of copper, aluminum, and non-ferrous metal alloys are of course much more expensive, but they have a longer service life.

Protective coatings for metal tiles

To increase service life, metal sheets are coated with special layers of protection. One of the most optimal budget options The coating is considered to be made of polyester. However, despite the low cost and far from little choice colors, this coating is not resistant to fading and various damages. But the low price makes this product a frequently purchased building material.

A denser coating is made from matte polyester. A product with such a protective layer is very similar to ordinary ceramic tiles. Its service life is automatically increased due to a denser layer of protection.

Pural - this type of protection is based on polyurethane. Distinctive feature this coating is considered to be free of deformation under the influence sunlight, in other words, due to this coating, the original color is preserved for a long time. Metal tiles with such a coating are not much more expensive than those with ordinary polyester.

PVDF is a protective coating based on polyvinyl fluoride. It is applied in a thin layer, but despite this it is considered one of the most stable. It has a fairly long service life and, accordingly, a high price.

Plastisol is applied in a relatively thick layer, but has excellent protection against various damages.

Metal tiles - profile types

All existing types metal tiles differ both in the material for the base and the coating for protection, as well as in the profile height and shape. Of course, reliability and strength directly depend on the thickness of the profile. This is especially important for installing roofs in areas where large amounts of snow may fall. Accordingly, the thicker the profile, the more reliable and durable the roof will be.

Types of metal tile waves differ in two parameters: height and pitch. A wave with a height of 23-35 mm and a pitch of 350 mm is considered standard.

Most often, there is a profile with a thickness of 40-45 mm on sale. The most popular shape of this profile is S-shaped. Monterrey and Andalusia metal tiles have a similar shape.

There are also such quite popular profiles as Joker, Shanghai, Banga, Modern. Cascade metal tiles are no less in demand - they are attractive with their original profile shape. Of course, they are all different from each other in pitch and height, it depends on them appearance roofs.

Metal tiles - dimensions

There is more than one manufacturer of metal tiles on the construction market; the sizes of the products they produce are also very diverse - widths from 1100 mm to 1200 mm, lengths from 800 mm to 8 m (the length can also vary depending on the customer’s wishes). Today, manufacturing companies have a popular service for cutting products according to the customer’s stated dimensions.

The thickness of the material also does not have clear numbers. It ranges from 0.45 mm to 0.5 mm. Naturally, the weight of the product is also different. It directly depends on the material used for the base and the type of coating for protection. Weight can be from 3.6 kg to 7 kg per square meter. These indicators are used when calculating rafter system under metal tiles.

How to choose the right metal tiles

When choosing a material for roofing, you need to carefully study its appearance, polymer coating and metal density.

The color range of metal tiles is quite wide, that is, you can choose the color based on your tastes, or combining it with the general color scheme the entire site or with the design of neighboring buildings. They mainly buy those colors that are closest to natural shades ceramic tiles. Green tint colors are often popular because they provide the roof with color harmony with the surrounding greenery of nature. When choosing a roof covering of other colors, you need to be careful so that your house does not turn out to be too colorful.

Experts advise choosing the type of metal tile based on climatic conditions of this area. And if in your region in winter period When a large amount of snow falls, buy material with a metal base and at least 0.5 mm thick.

The type of polymer protective coating must be selected based on the intensity of atmospheric phenomena in the area. For example, if your personal plot is in middle lane, where in summer period If it is not too hot, and in winter there are no severe, prolonged frosts, then tiles with a protective polyester coating are quite suitable for you, which in turn will allow you to save money when purchasing.

In the case when you are roofing a house located in an area with strong temperature fluctuations or near the sea, where there is a large amount of vapor in the air sea salt, that is, with a high content of aggressive substances for building materials- you need to select a higher degree of protection. In such cases, you need to pay attention to material with protection made of pural, polyvinyl fluoride or plastoisol.

As when purchasing any other product, read the quality certificate for this product. This “acquaintance” will provide an opportunity to buy a quality product from a reliable manufacturer and not waste money in vain.

We hope that the information you received about the types of metal roof tiles will help you buy high-quality material suitable for use in the conditions of your area.

Disadvantages of metal tile roofing and ways to eliminate them

Unfortunately, at the moment there is no material that does not have any disadvantages; metal tile roofing also has them. First of all, this is the possibility of condensation settling on metal surface with a significant difference in temperature indoors and outdoors. Constant repetition of this phenomenon can lead to corrosion processes. For this reason, you should follow the recommendations for laying layers of under-roofing film, which is a vapor barrier or a water barrier.

At the stage of laying the material, a serious disadvantage may be increased waste, especially if the roof of the house has a complex geometry.

Metal is a noisy material, especially when it rains. To protect the residents of the house from unnecessary sounds, it is enough to lay a layer of mineral wool insulation when installing the roof, in addition to the layer of vapor and waterproofing. Thus, all the shortcomings of a metal tile roof are eliminated quite simply.